Modern manufacturing machines can make India’s most loved snacks aloo bhujia, soya sticks, Navratna mixtures, cheese ball etc.

New Delhi, 10th September, 2020 – Kanchan Metal (P) Ltd, leading and pioneer company offering food processing machines has recently launched a varied number of snack machines with an aim of providing global technology with local support. They have launched Automatic Bhujia/Sev Production Line, Automatic Moong Dal processing line, Mixture line, Automatic Extruded Snack line, Automatic Bakes extruded snack line, Sabudana frying line, Corn cooking and steeping line, Busket Elevator System and Universal Extruder for twist and Corn chips.

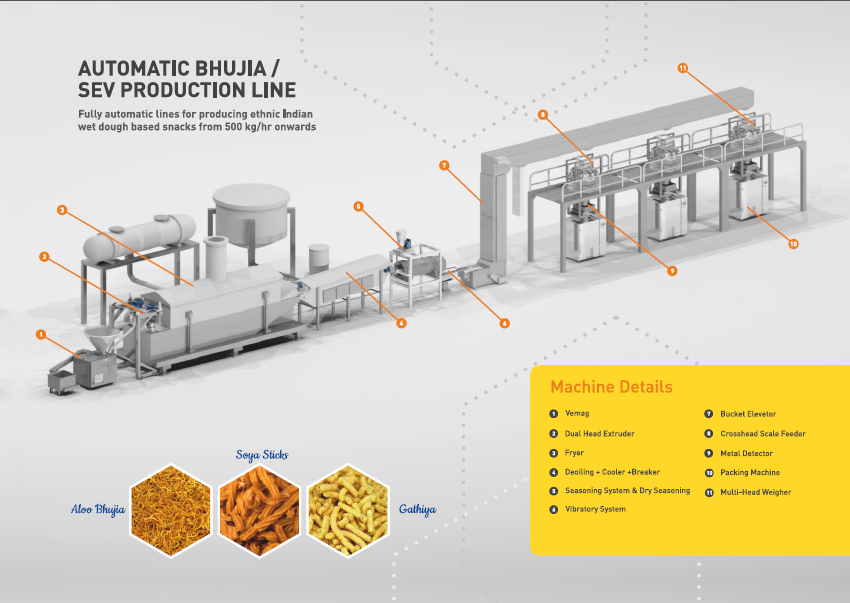

The automatic Bhujia/Sev production machine it is a fully automatic lines for producing ethinic Indian wet dough based snacks from 500Kg/hr onwards, whereas the automatic moong dal processing line would take 500kg/hr onwards upto 3000kg/hr. The mixture line machine which is a fully automatic line for weighing and blending of traditional one of the favourite Indian snack mixtures can take 500kg/hr onwards.

Mr Raghav Gupta, Director, Kanchan Metals said, “We are delighted to launch of our new products for India which is the world’s sixth-largest food industry. With our consistent efforts and advanced technology, we are aiming to transform the Indian food processing industry’s environment by combining food processing technology with applications focused on big data analytics, blockchain technology, IOT & computer AI as well as a large-scale virtual process management, which is crucial for our country. Kanchan Metals is known for the products and credibility and our new product will be a testimony of our prowess”

They have launched another set of machine which can make different design and shaped of chips, thereby it is the automatic random extruded snacks line which can make snack of any random shape and size. Automatic line for producing extruded snack line like cheese ball, rings, puffs (this snack line is very much famous between the kids because of the twist of shape and cheesy taste). They also have the Sabudana frying line the fully automatic line with multiple frying zones for Sabudana product, than they have the corn cooking & steeping line for corn o make corn masa used in tortilla chips and extruded snacks. Lastly, they have the basket elevator system with overlapping bucket design for spillage free conveying of product and Universal extruder for twist and corn chips.