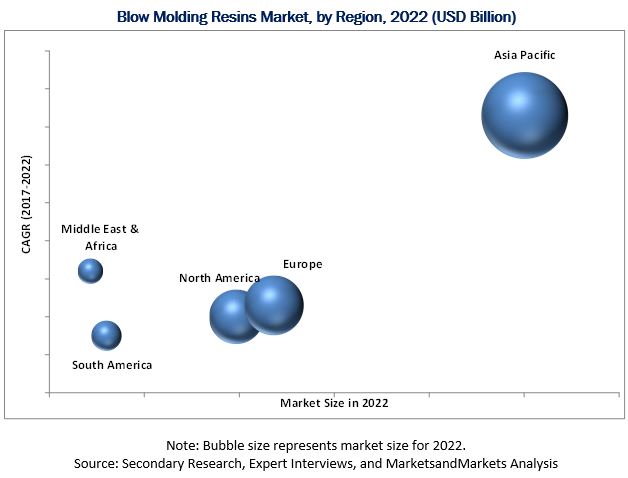

The Asia Pacific blow molding resins market is projected to grow at the highest CAGR during the forecast period. The growth of the Asia Pacific blow molding resins market can be attributed to the presence of the leading blow molding resins producers in the region. Moreover, the growing demand for blow molding resins in packaging applications, such as pharmaceutical and food & beverage products in countries, such as China, Japan, and India also contribute to the growth of the Asia Pacific blow molding resins market.

The increasing per capita expenditure on healthcare, personal care, and food products, large consumer base, growing urban population, low labor costs, and easy availability of raw materials are attracting international pharmaceutical, chemical, and food & beverage manufacturers to shift their production facilities to the region, thus creating high demand for the blow-molded products produced by blow molding resins in these industries. The Asia Pacific is the global manufacturing hub for the chemical industry, accounting for more than 50% of global chemical production output; this increases the demand for products, such as cans and containers, produced with the use of blow molding resins in the chemical industry.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=8448983

The target audiences for the blow molding resins market are as follows:

Manufacturers of Blow Molding Resins

Blow Molding Resin Compounders(those who prepare plastic formulations by mixing or/and blending polymers and additives into process ready pellets)

Blow Molding Resin Converters (those who convert plastic resins and compounds into finished products)

End-use Industries, such as Pharmaceutical, Food & Beverages, Personal Care, and Chemical, among others

Automotive & transportation is the second-fastest market for blow molding applications. Blow molding resins are used to produce auto-parts, such as panes and railings, bumper support, fenders, mudguards, door locking systems, consoles, garnish pillars, cockpit systems, and fuel tanks. Polyethylene, polypropylene, polyvinyl-chloride, polystyrene, polyethylene terephthalate, and acrylonitrile butadiene styrene are the commonly used blow molding resins in the automotive application. These resins are preferred in automotive applications owing to their minimal corrosion, which leads to longer vehicle life, substantial design freedom, innovation and creativity in vehicle development, and flexibility in integrating components.

Exxon Mobil (US), LyondellBasell (Netherlands), DowDuPont (US), SABIC (Saudi Arabia), INEOS (Switzerland), Solvay (Belgium), Formosa Plastics (Taiwan), Chevron (US), Eastman (US), China Petroleum (China), and Reliance Industries (India), among others are the key players operating in the blow molding resins market.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=8448983