There will be a much greater need for flexibility in the future, both for transport service providers working on behalf of other companies and for large companies with their own fleets of vehicles, in order to be able to cope with a wide range of different transportation assignments by road. This is not about swap body systems, silo vehicles or container lorries. The transport hardware needed for them is offered by mass produced products whose solutions cover a clearly defined sector of transport services. But there are also countless additional mobile silo systems, interchangeable containers, flats, aggregates and machinery in the logistics loop that need to be transported by HGV. Flexibility will be needed among transport companies in order to secure more utilisation for their lorries, especially in times of economic fluctuations. Adaptation solutions that enable lorries to be used flexibly for various transportation assignments are an economically effective concept.

Hook roll-off tippers become a universal solution

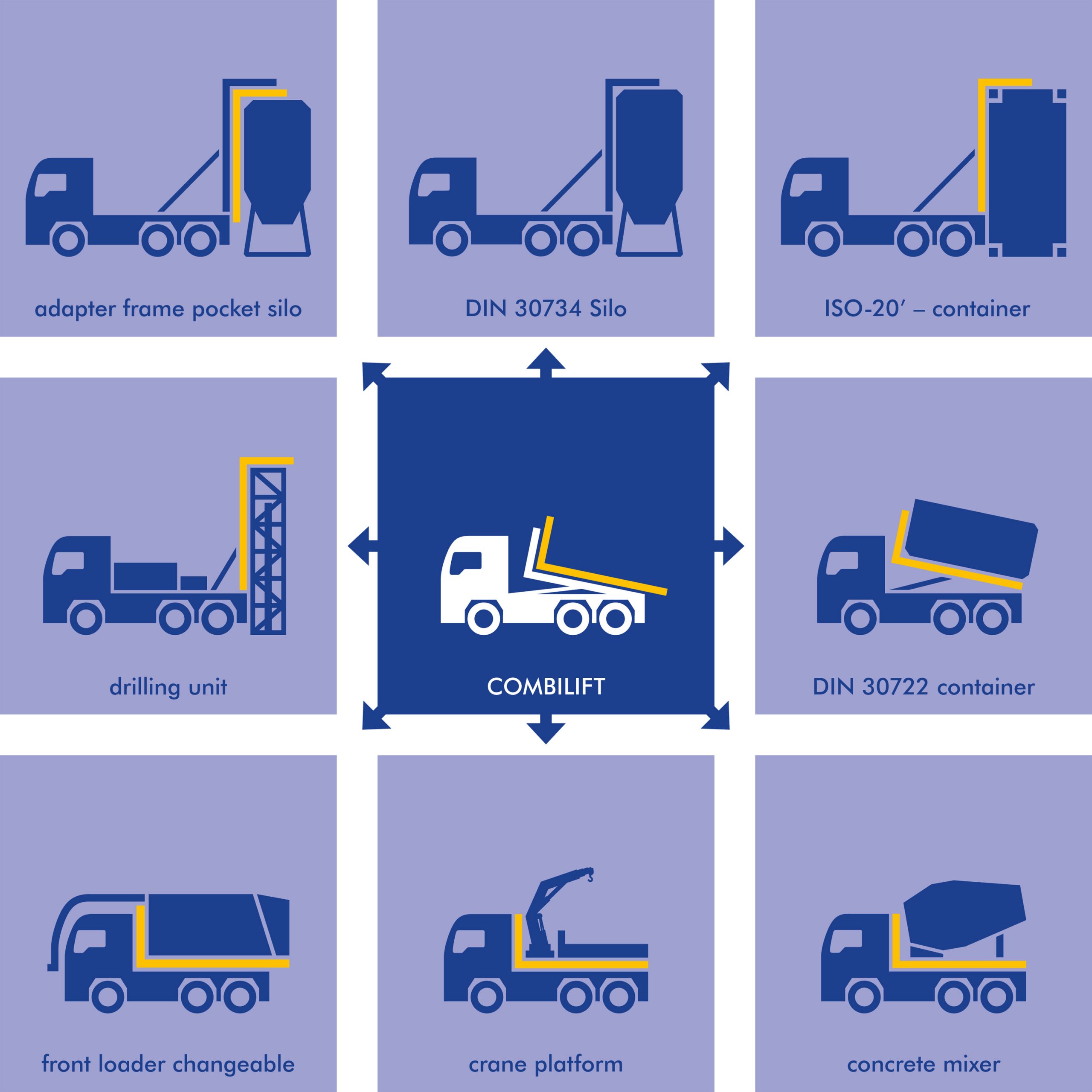

The COMBILIFT from velsycon, the manufacturer based in Wildeshausen, Germany, can do more than the standard hook roll-off tipper. An HGV with this interchangeable body becomes a universal load carrier.

Be it a supported swap body, DIN 30722 container, 20-foot shipping container, interchangeable silos, flats or filter silos – this interchangeable body transports anything and can be equipped with a suitable adapter if required. As well as DIN silos and DIN containers, the COMBILIFT can also hold two pocket silos, for example, picking them up and setting them down vertically like DIN silos using the CL-2T adapter frame. This is facilitated by a tipping and placing angle of over 90 degrees. In contrast to permanently installed equipment, this adapter frame is only carried when required and therefore doesn”t reduce the payload available for other transportation assignments.

Tried and tested, sometimes even detachable adapter solutions make this extremely flexible concept possible for universal handling and transportation technology. The hook arm on the COMBILIFT can be moved hydraulically within its frame. As a result, it offers a unique flat container mount, offering a decisive advantage over standard roll-off tippers, for example when handling mobile refuse compressors in underground car parks.

In addition, interchangeable bodies and flats for the transportation of construction machinery, power units or bagged goods needed on building sites can still be transported. Excess loads on trailers and on-site storage are easily achieved thanks to small loading angles.

Skip loader also takes DIN silos up to 22.5 m3

The silo skip loaders in velsycon”s SASK range can handle and transport DIN silos up to 22.5 m3 as well as standard skips and PFT silos especially designed for skip loaders. The flexibility of this superstructure type can also be enhanced by the SASK-2T adapter frame in order to be able to pick up and carry two pocket silos as well.

Thanks to in-house 3D-CAD design and high production depth using the company”s own steel structures as well as the use of proven components, many transport solutions can be achieved by velsycon with maximum flexibility. Moreover, customised solutions can also be developed and realised, e.g. for vertical drilling technology, exchangeable concrete mixing units and other customer requests.

The range of applications extends beyond the construction industry because chemical granulates, for example, or animal meal, blasting agents, wooden pellets, road salt, filter dust and other materials are also transported and delivered in interchangeable silos.

Interchangeable silos are also an alternative to permanently installed upright silos, in particular when production resources need to be provided within a time limit. Time-consuming (construction) approval processes can thus be avoided. When interchangeable silos become available again at the end of production projects, they are removed and brought to another place to be reused.

Filter units mounted on DIN subframes, for example for wastewater treatment, are used with increasing frequency throughout Europe. The transportation and positioning process is significantly less time-consuming and cost-intensive in comparison when velsycon superstructures are used. No additional crane is needed for positioning.

At the Wildeshausen factory, the superstructures are developed, produced and installed on 2 up to 4-axle lorries provided by the customer. In addition, velsycon offers its customers complete vehicle manufacturer-independent.

Vehicle utilisation can be increased by 34%

velsycon also builds front loader collection vehicles to customer requirements as interchangeable superstructures that are fully ready for use. The hook roll-off tipper accommodates the entire unit consisting of lifting platform, compressor and compactor container. Once connected, the front loader collection vehicle is ready for use.

Studies of various market segments and fields of application undertaken by the Wildeshausen company showed that adapter solutions – either installed permanently on the lorry superstructure or with the aid of adapter frames – can increase vehicle utilisation by up to 34%.

German vehicle manufacturing is technically highly developed and is at the leading edge globally. The high level of performance, equipment and degree of safety is also reflected in velsycon systems.

Whether Russia, Spain, Greece, Scandinavia, the Far East or the Middle East – HGV transportation technology from velsycon is used in many countries worldwide. ** End of press release ** Download: www.pr-download.com/velsycon.36.zip