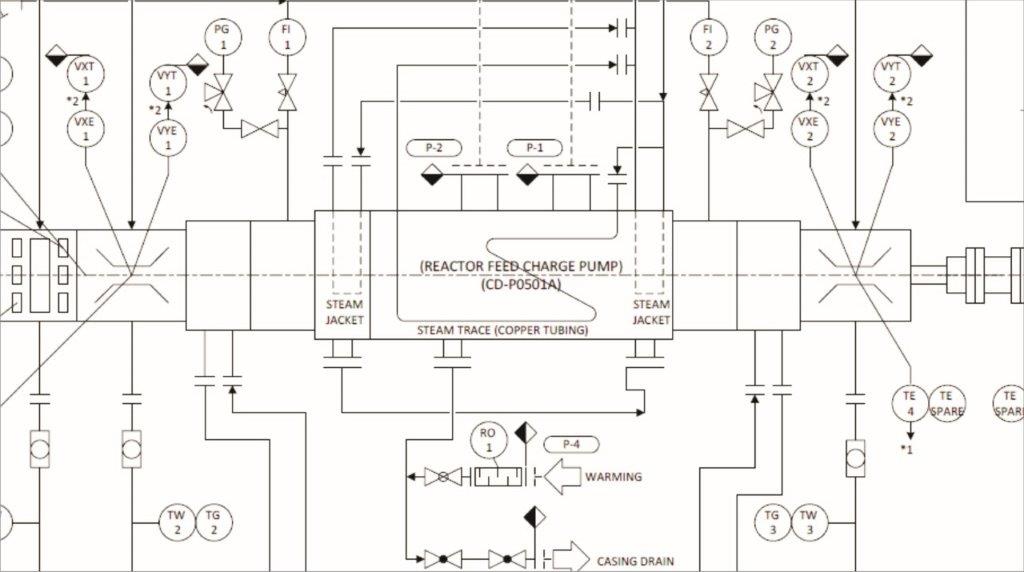

Established in 1912, EBARA Group has been at the forefront of developing some of the worlds most advanced fluid technologies. In the Fluid Machinery and System division, the creation of Process & Instrumentation Diagrams (commonly referred to as P&IDs), is one of the main tasks of the engineers in plant design. These serve as a standard document for the entire plant life cycle and comprise of different types of documents such as P&IDs, equipment lists, piping lists, etc.

“We were looking for a tool that would simplify and speed up the review and approval of documents such as P&IDs,” explains Hideki Fujieda, Head of the High Pressure Pumps Design team at Ebara Corp. “The manufacturing process requires that these documents be approved by the customer in advance. However, due to the involvement of several disciplines in the P&ID design, information was often repeated and duplicated. For this reason, the completion of the entire documentation took a lot of time.”

“With the Visio P&ID Process Designer solution from ITandFactory GmbH we have found a software solution for simplified P&ID creation and process documentation,” Fujieda continues. “A great added value of the tool: All data and information is stored in the database and is accessible to all engineers involved at the various levels.”

Besides these advantages, the price-performance ratio and the simplified implementation convinced Hikedi Fujieda and his team of the software solution: “The Visio P&ID Process Designer is a very cost-effective solution. With its introduction, we were able to significantly reduce our pain points and the time required to create P&IDs. It has an integrated tool for automatic testing, which also helps to reduce manual efforts. For these reasons, after the successful implementation of the initial phase, we have now further extended the tool to a larger team.”

For further information please visit www.visiopid.com