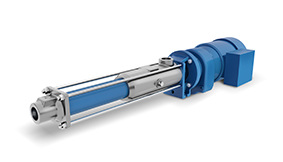

RADOLFZELL, Germany (February 18, 2020) – Allweiler launches the next-generation AEB-DE progressing cavity pump series of four pump sizes that share one installation footprint and are capable of bi-directional flow. Combining proven features from two dosing pump ranges with newly optimized rotor and stator geometries, Allweiler customers benefit from the utmost in accurate dosing of high viscosity and particulate-filled fluids in one compact, versatile series.

In addition to simplifying pump selection and the quote process, the space-saving modular setup of the Allweiler AEB-DE dosing pump series makes standardizing simple without regard for required flow rate or fluid characteristics. Skid builders will simply outfit the installation space for the specified pump according to the operating data provided. This flexibility facilitates future variations in needed flow rates with simple changeouts of conveying elements. No cost-intensive refurbishments or adjustments to piping are necessary.

“Pump skid builders and their customers need and expect more than stable pump performance and accurate dosing capabilities,” said Daniel Stirpe, Vice President, CIRCOR Industrial Pumps EMEA & APAC. “Today cost-effective pricing and reasonable delivery times to position their customer for market success are just as important.”

Going beyond the expected reliable pump performance and accurate dosing capabilities, the AEB-DE series raises the bar with incremental benefits that position customers for success with flexibility, efficiency, safety and uptime features. The innovative design of the new suction casing has three additional closed drillings that can be used for various functions. Customers have the ability to fill the pump, to drain it or to install additional auxiliaries if needed.

In addition, the new design of the casing ensures permanent flushing and cooling of the seal as it is located in the flow of liquid. Due to this, the pump can also be installed vertically without any risk of seal failure. To further ensure safe plant operation and preventable breakdowns or damage to the pump, the AEB-DE series can be upgraded with smart dry running protection or a pressure sensor.

The AEB-DE pump series delivers reliable high volumetric efficiency for all of the following dosing needs:

– PULP & PAPER: additives, PVOH, sizing agent, starch, dye, optical brightening agent, polymer

– MARINE: oily water, urea, bilge, seawater

– GENERAL INDUSTRY: caustic soda, glycol, paints, glues, sealants

– CHEMICAL PROCESSING: acid, leachate, catalysts, condensate, additives

– MINING: polymer, tenside, catalyst

– FOOD: oil, sauce, chocolate, liquor

– POWER: urea, waste oil, slop oil