Process observation using sight glass devices

Sight glass devices allow detailed observation of processes without requiring complex and often expensive sensor systems. In this article, we explain some common types of sight glasses, their advantages and disadvantages, as well as some important criteria for design and selection.

Central component of a sight glass device is a chemically and physically highly resistant glass, in most cases tempered borosilicate glass. If the operating temperature is above the nominally allowable 280 °C, a mica disc can be used to improve the resiliency of the glass for operating temperatures up to 300 °C. Above that, other glass types like quartz or sapphire based glass can be used.

A sight glass device allows observation of any process without requiring any moving mechanisms or electronics. By avoiding such systems, the plant remains mostly maintenance-free. If the chemical and physical conditions have not been appropriately considered however, parts of the sight glass device can be severely damaged, for example by corrosion or high temperatures.

The most important bits of information to provide to your sight glass supplier are:

-Process medium (fluid inside the plant, but also unusual external influences like sea water)

-Expected operating temperature

-Operating pressure

-Type, standard and nominal size of any connections

Common types of sight glass devices and their applications

Sight glass devices can be coarsely categorised into three general types with different advantages and disadvantages. These categories are tank sight glasses, flow sight glasses and level indicators. This section explains the three categories and sheds light on some of their special properties.

Tank sight glasses

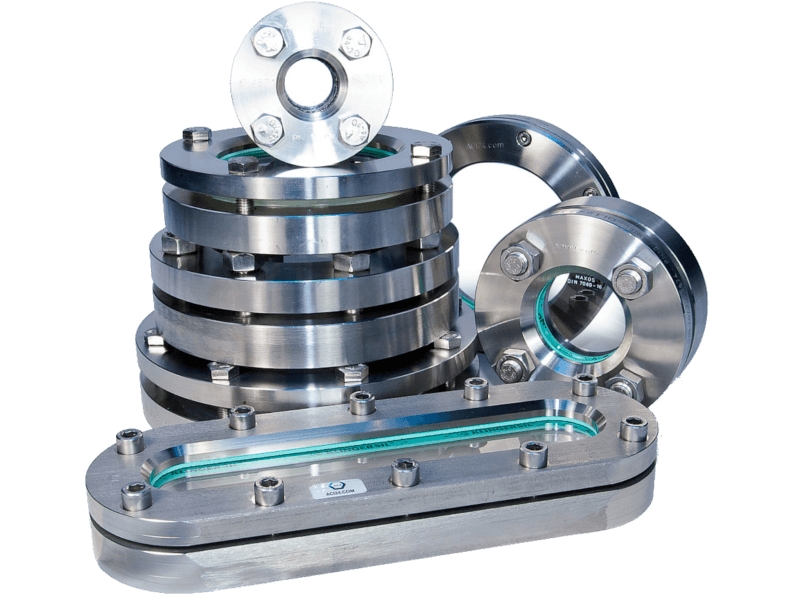

Tank sight glasses are flat steel flanges that are, depending on the specific type, either welded into the wall of a pressure vessel or fixed to carrier flanges. Some common types of tank sight glasses are shown in Figure 2.

These sight glass fittings can be installed as required in processing plants of any kind.

Tank sight glasses are primarily defined in the German Industrial Standard documents DIN 28120 and DIN 28121. Additional variations have been effectively established as standards in practice based on these two documents.

ACI type 320 according to DIN 28120 (Figure 3, left side) is a type of sight glass fitting to be welded into the side of a pressure vessel. The glass plate, together with the inside gasket, is inserted into a recess on the base flange. On the outside, a cover flange is used to fix the glass plate to the base flange and apply a defined pressure to the system of base flange, gasket and glass. This allows for a comparatively easy exchange of broken or damaged glass plates. The process is shown in detail in the video instruction here: https://youtu.be/C2NKz_15_pE. Alternatively, you can use the QR code in Figure 4.

Figure 4: ACI instructional video “changing round sight glass plates”

In the presence of corrosive process media or high temperatures (above 280 °C), the sight glass disc can be protected from chemical influences by an added mica layer, simultaneously increasing the allowable operating temperature to 300 °C.

Sight glass fitting of type 321 according to DIN 28121 are intended for mounting on a flange.

The sealing method for this type is different from type 320 in that it uses a PTFE enclosed resilient gasket system in off-load contact. As shown on the right side of Figure 3, this creates a nearly completely closed fitting for the glass disk. Sight glass devices according to DIN 28121 do not need to be disassembled for installation or maintenance. Replacement of the glass disk or gasket is not intended in the field, and should be performed by the manufacturer if required.

Based on the definitions of DIN 28121, ACI Industriearmaturen GmbH has designed and manufactured tank sight glasses suitable for temperatures above 500 °C and pressure exceeding 100 bar.

Flow Sight Glasses

Figure 5: Typical flow sight glasses. From left to right: Welded body with flange connections, tubular sight glass with impact protection shell, intermediate flange sight glass (here installed between two welded neck flanges).

Flow sight glasses are often equipped with flanged connections and can be installed in piping like any other industrial valve. Most types are also available with welding ends or threaded connections.

The most basic type, as shown in Figure 5 on the left side, has a straight main body and two opposite sight glass windows. Extrapolating from this basic type, three-way or four-way sight glass devices as well as sight glasses with multiple viewports are also available, some of which can be seen in Figure 6.

Figure 6: Additional variations of flow sight glasses

With an appropriate mechanical design and the right materials for body, glass, bolts and gaskets, this type of sight glass can be built for applications operating at 1000 °C or 1000 bar.

For improved observation of the process fluid, tubular sight glasses as shown in Figure 5 in the middle can be used.

This type of sight glass offers 360° view of the process fluid and is almost completely without wake spaces. These properties make this type of sight glass especially suited for applications requiring hygienic conditions at relatively low pressure (maximum 16 bar). The lack of wake space also reduces drag within the sight glass body. The relatively large open glass area frequently often necessitates the addition of an impact protection shell made of acrylic glass, as shown in Figure 5.

Due to manufacturing limitations the maximum allowable pressure for this type of tubular sight glass is significantly lower than for other flow sight glasses, especially in large nominal sizes, as shown in Figure 7.

For significantly higher temperatures and pressures, tubular sight glasses can also be manufactured in an intermediate flange design, which is available in quartz glass in addition to borosilicate glass. One such sight glass is shown in Figure 5 on the right, installed between welded neck flanges.

Figure 7: Maximum allowable operating pressure for ACI type 620 tubular sight glasses

Level indicators

Figure 8: typical elongated sight glass fittings as level indicators

Level indicators can be considered a special type of tank sight glass. The viewport is, as shown in Figure 8, narrow and long. Such a sight glass, installed into a tank, offers an easy way to observe the tank liquid level from outside without requiring floaters or other additional parts. Clear and colourless liquids can be more easily visualised by using a “reflex” glass. This type of glass is serrated on the inside, improving visibility of the liquid”s meniscus as shown in Figure 9.

Figure 9: The difference between reflex and transparent sight glasses according to DIN 7081

For some applications a bypass level indicator can be desired. For these cases, the sight glass can be built with a fully closed housing and different types of process connections, as shown in Figure 10.

Figure 10: Different types of bypass level indicators

If observation from multiple angles or a backlit view is desired, a sight glass of type 340 as shown in Figure 11 can be used. This type of sight glass can be equipped with threaded connections, welding connections, flanges, or any other desired process connection, and is uitable for high pressures above 35 bar and temperatures up to 243 °C.

Figure 11: ACI Type 340, a fully closed level indicator sight glass with two viewports

Important considerations when using sight glass devices

1.Maintenance intervals

Maintenance requirements of sight glasses depends highly on the operating conditions. In case of corrosive fluids, especially alkaline substances, a regular replacement of the glass disk and inner gasket is recommended, independently of observable corrosion on the glass. If the chemical influence on the glass is unknown, the sight glass should be inspected in regular intervals. Cloudiness, deformation, signs of corrosion or superficial scratches and fissures significantly reduce the safety of the sight glass. If any of these effects are observed, the glass should be replaced immediately. Replacing the glass disk always requires replacing the inner gasket as well.

2.Viewport size

A larger viewport generally requires an increase in glass thickness compared to a smaller viewport for the same conditions. It is prudent to keep the glass disk sizes within the definitions of DIN 7080, as the sizes given in this standard are generally available with very short delivery times and at significantly lower cost than specially designed glass disks. This is especially important considering the procurement of spare parts during the lifetime of the plant.

3.Gasket materials

The gasket material has to be selected according to the operating conditions. If the gasket is not suitable for pressure, temperature or process fluid, leakages during use are very likely. Common gasket materials are bound aramid fibres, graphite and PTFE

4.Glass material

The most commonly used material for sight glasses is borosilicate glass 3.3. This type of glass possesses high resilience against most chemical influences, especially acids, and can be used up to 280 °C, or 300 °C with a protective mica disk. For higher temperatures, glass based on quartz or sapphire is often used. In addition to the higher temperature tolerance, sapphire glass is also much more scratch-resistant.

5.Body material

Just like gaskets and glass, the body material must be appropriate for pressure, temperature and fluid. Usually, this is the responsibility of the sight glass manufacturer.

6.Type, standard and size of connections

To install the sight glass device into the piping, the correct connection type, standard and size must be selected. It is very important for the sight glass manufacturer to be provided with this information during the initial request for quotation!

7.Special requirements

Some applications can pose additional requirements, like reduced wake space, additional sensor connections or rounded corners to improve draining of liquids. In addition, the inner surface of the sight glass can be coated, for example with PTFE, to improve chemical resilience.

8.Special equipment

Most sight glass devices can be equipped with additional features like LED or halogen lighting, wiper mechanisms or spray nozzles to clean the inner glass surface. Heating systems for the sight glass windows or the whole body are likewise available on request.